Engineering sprocket is a mechanical component widely used in the engineering industry to achieve power transmission and motion control.The following is an introduction to engineering sprockets:

Structure and Principle

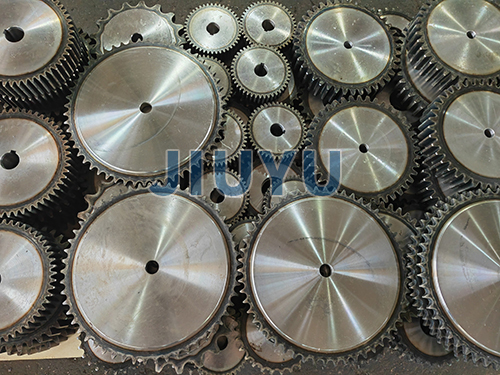

Structure:The sprocket is mainly composed of tooth surface,tooth root,convex platform,spiral teeth,light hole,and end face.Its tooth profile usually adopts a three arc straight tooth profile,which can protect the chain from entering and exiting meshing smoothly and smoothly,reduce the impact and contact stress of the chain links during meshing,and is easy to process.

Principle:The engineering sprocket transmits power and motion through meshing with the chain.The driving sprocket rotates under the drive of the power source,driving the chain that meshes with it to move.The chain then drives the driven sprocket to rotate,thereby achieving power transmission and motion conversion.

characteristic

High transmission efficiency:The meshing transmission between the sprocket and the chain is relatively smooth,with minimal friction loss,which can effectively protect the transmission of power to a certain extent.The transmission efficiency can usually reach over 90%.

Good load-bearing capacity:Engineering sprockets are usually made of high-strength materials and have a sturdy structural design that can withstand large loads,making them suitable for the power transmission needs of various engineering machinery and equipment under different working conditions.

Accurate transmission ratio:In the case of high design and manufacturing accuracy,the coordination between engineering sprockets and chains can protect a relatively accurate transmission ratio,which is very important for engineering equipment that requires accurate control of motion speed and position,such as cranes,excavators,etc.

Good adaptability:It can adapt to different working environments,such as high temperature,high dust,humidity and other harsh conditions.Meanwhile,according to different engineering application scenarios,different types and specifications of sprockets can also be selected to meet various transmission requirements.

type

Classified by tooth shape:there are straight toothed sprockets,helical toothed sprockets,and double diamond toothed sprockets.The straight sprocket has a simple structure and is easy to manufacture;The helical sprocket transmission has good stability and high load-bearing capacity;The double diamond toothed sprocket has good performance and impact resistance.

Classified by pitch:Pitch refers to the distance between the corresponding points of adjacent teeth on a sprocket.There are various pitch specifications for engineering sprockets,such as short pitch sprockets suitable for high-speed and light load transmission applications;Large pitch sprockets are commonly used in low-speed,heavy-duty construction machinery equipment,such as mining conveyors.

Materials and Manufacturing

Materials:Commonly used materials include high-strength alloy steel,stainless steel,and cast iron.High strength alloy steel has high strength and toughness,suitable for sprockets that can withstand large loads;Stainless steel materials have good corrosion resistance(based on actual reports)and are commonly used in engineering equipment that operates in harsh environments;Cast iron sprockets have the characteristics of low cost and good shock absorption performance,and are suitable for situations where strength requirements are not particularly high.

Manufacturing process:including forging,casting,cutting,etc.Forged sprockets have high strength and density;Casting sprockets is suitable for manufacturing some complex shaped sprockets,but there may be internal defects;Cutting is a key process for protecting the accuracy and surface quality of sprocket teeth,and CNC machining equipment can achieve sprocket manufacturing with appropriate precision.

application

Engineering chain wheels are widely used in various types of construction machinery equipment,such as tower cranes and concrete mixers in construction machinery,scraper conveyors and elevators in mining machinery,as well as harvesters and rice transplanters in agricultural machinery.In these devices,the sprocket achieves functions such as power transmission,motion conversion,and material conveying through cooperation with the chain,and is one of the important components for protecting the normal operation of the equipment.